Lasersoft Changes 3D Workstation©™

AND IF you are still making changes at your 5-axis laser machine controller,

you are throwing invoicing dollars down the proverbial toilet.

Learn the secret of the most successful laser prototype shops in the world.

you are throwing invoicing dollars down the proverbial toilet.

Learn the secret of the most successful laser prototype shops in the world.

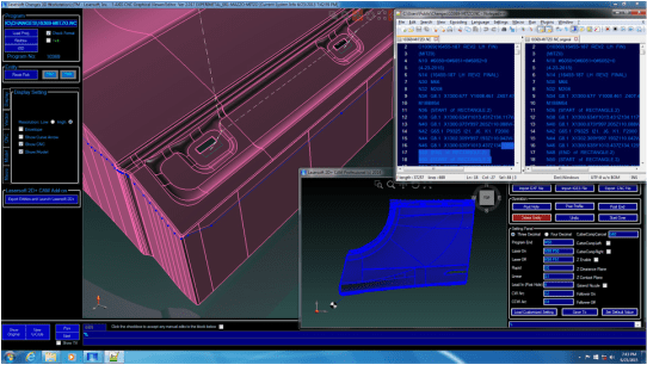

Move/Rotate/Blend or Offset multiple 5 Axis Laser blocks with ease AND accuracy.

When you take ALL edits offline, your machine can make MORE parts! more PARTS = more PROFITS!

Above screenshot shows box select being used to correct with OI(order independent) technology

Specifically Designed for 5-Axis laser cutting machines, LC3D provides easy to use tools to manipulate the cutter path without any specialized knowledge. In fact it is also a wonderful training tool for new laser operators where they can play in an environment that allows them to safely manipulate and test the program.

LC3D©™ 2021 Standard Features:

Specifically Designed for 5-Axis laser cutting machines, LC3D provides easy to use tools to manipulate the cutter path without any specialized knowledge. In fact it is also a wonderful training tool for new laser operators where they can play in an environment that allows them to safely manipulate and test the program.

LC3D©™ 2021 Standard Features:

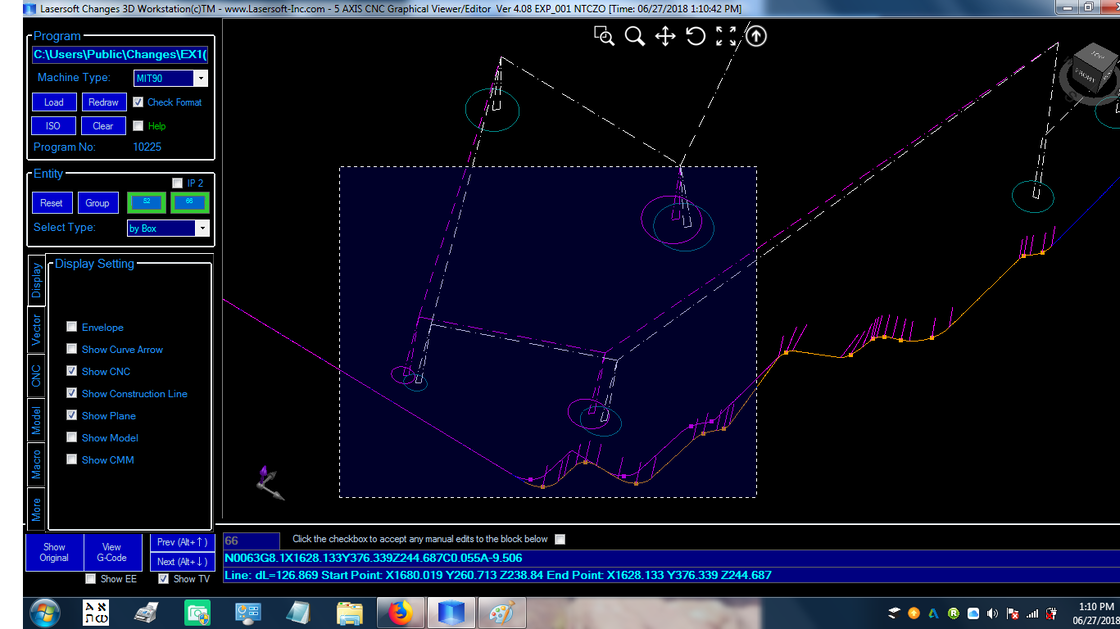

- Visually edit your 5-Axis Laser program with sophisticated tools, not simply xyz translate moves...

- Macro editor: HOLE, SLOT, RECTANGLE, HEX, PLANE, Etc...

- Displays ALL motion including: 3 Point Arc, Linear Interpolation, Rapid moves, all Macros (up to 10).

- Order independent and Box Selection for easily changing multiple program sections simultaneously

- Split linear or circular moves to add tabs or create additional control points

- Nozzle in or out for those sprung out panels

- Construction lines for creating any possible move direction from the cutter path and working within any plane that you can create easily from the existing part geometry or load in you part model using IGES format.

- Mirror Image

- Simplify Arcs: Convert Multipoint Arcs to 3 point arcs

- Rotate ALL or portions of your part program about ANY axis or unique rotation vector created for existing holes, lines, etc.

- IGES Import/Export for 3D, DXF for 2D

- Car Coordinates or Robot/Machine coordinates

- Additional 3D or 5-Axis Laser interpreters

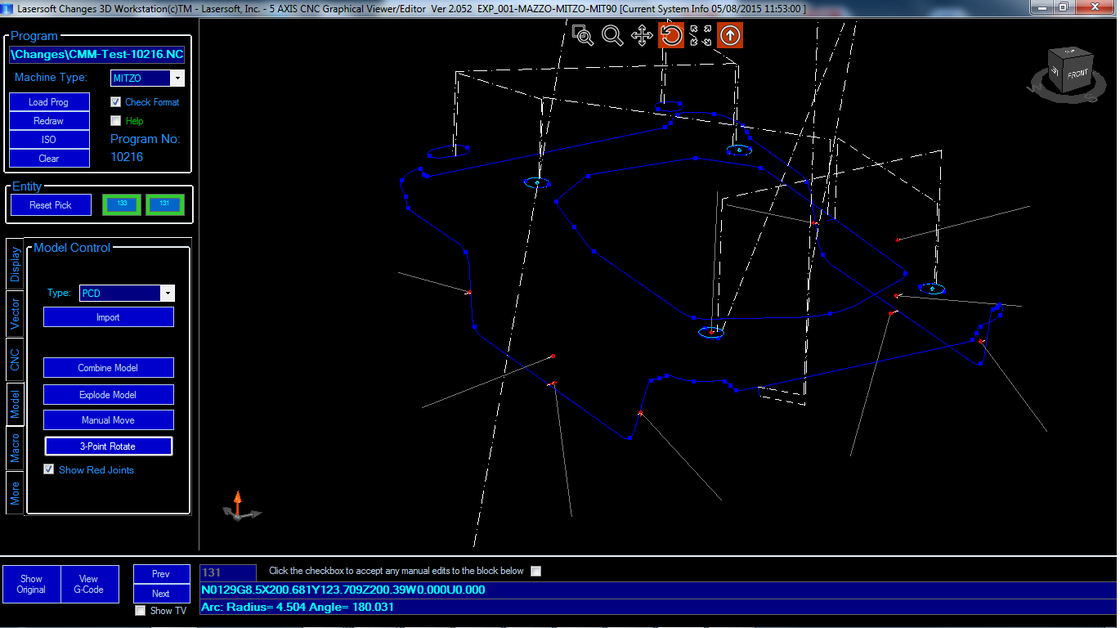

- CMM or other Inspection Data Interpreter

- 2D+ Laser interpreter and Post processor

- Convert programs from 3D to 2D, useful when using your 5-Axis to teach blanks

Above screenshot shows CMM Data for most accurate and quick changes

If you can relate to any of these statements then you may need LC3D

If you can relate to any of these statements then you may need LC3D

- Why does it take so long to get a part approved for cutting?

- Why does it take so long for the operators to make changes and cut the next part?

- Why does it seem like the machine is not making sparks for 25% of the day, but instead is sitting idle?

- Why can't I get the production volume out that I estimated?

- I have late deliveries because I cannot predict production accurately

- I don't know how my edits will turn out until after I cut the next part

- I have customer complaints about part quality or turn around time

Got Questions?

*to qualify for a live demo your company must be 5-Axis Laser Cutting end users

Are you interested in adding this software to your machine or as a package with your machine sale -OR- are you interested in being a distributor of Lasersoft Changes 3D Workstation©™? Email us: sales@lasersoft-inc.com

Are you interested in adding this software to your machine or as a package with your machine sale -OR- are you interested in being a distributor of Lasersoft Changes 3D Workstation©™? Email us: sales@lasersoft-inc.com