|

Manufacturing companies constantly attempt to provide higher quality product, whereas creating a shot to be more productive and sustainable with the assistance of the most recent technological trends. Additive processes like 3-D printing, versatile electronics engineering, and various innovative technologies can outline succeeding generation of client devices. Robots are only one of the numerous new technologies that are getting increasingly widespread in our industry.

Utilizing Robots for Manufacturing With integral detector systems, robots are capable of not only automating repetitive tasks, however additionally performing extra advanced processes and dangerous operations which may place an individual's employee in danger. Fast, precise and reasonable, robots have the capability to do things humans merely cannot — however before worrying regarding robots taking on every manufacturing job, consider what the U.S. Labor Department should say regarding this technological shift. Industry Impacts It is calculated that 40-50% of all jobs could be automatic over consequent 2 to 3 decades, which suggests regarding 2 of all jobs annually. Last August, the U.S. Labor reportable that the speed of job creation every month is around 2.4%. due to the steady increase in job creation over the last years, the task loss to robots is actually twelve to fifteen times under current economic indicators. While jobs will still become progressively automatic, this may not essentially finish in net job loss for a company, as new jobs may be created at the constant time. because of their edges to the business and talent to conduct extraordinarily advanced manufacturing processes, robots provide very important potential edges to the whole population. At Lasersoft we make significant efforts, up front, to keep it simple. Also, a good, solid engineering design is ABSOLUTELY necessary from the beginning of any complex system, YOU MUST HAVE MECHANICAL, ELECTRICAL AND SOFTWARE engineers that can work together from the concept through completion in order to gain the maximum potential of any system. At Lasersoft, our program managers are experienced in all 3 disciplines of engineering technologies (Mechanical, Electrical, and Software) so that, when we work together with you from the beginning until the end, the result is a turn-key solution that just works.

0 Comments

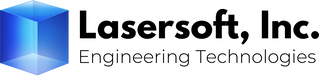

Making it with Lasers The uses and applications of laser cutting? In any one day we can be doing prototyping and testing parts for product design companies, who are making the most of the quick turn around and no set up costs, large commercial scale runs of products, utilizing the laser machines repeat-ability to create identical cuts, speeding up the process and allowing incredible intricacies in a wide range of materials. The laser used here emits infrared light which is invisible to the human eye. Considering that this light cannot be seen, it is difficult to tell where the beam is being directed. Polycarbonate absorbs infrared light very well. I recommend you head over to home depot and purchase several pairs of clear polycarbonate safely glasses. It wont protect you from a focused beam however so you must always avoid any contact with the beam and since it is invisible you should be trained on laser safety before entering into the shop or laser enclosure and of course, do not fire the laser irresponsibly. 5-Axis Lasers Three-dimensional laser cutting systems offer the ultimate in accuracy and flexibility for users across a wide range of complex laser applications. The unique flexibility of these 5-axis systems, combined with expanded teaching functions, make them extremely powerful tools. They significantly decrease the time and manpower required to produce complex parts and provide the greatest degree of accuracy and cost efficiency. While other laser cutting, services will simply work on a flat sheet, bar, and plate, 5 axis service works towards creating high-quality 3D parts. Sometimes these designs can mean that we need to work with a different form of material. We have over two decades of experience in the 5-axis dimensional cutting industry. We constantly work and check on a product to ensure that it is created to the highest of standards. We understand that a design is going to be something that is looked at and appreciated, so you can be positive that any work we do will cater to your high standards. There isn’t any wonder why 5-axis laser cutting division is so highly regarded by the automotive industry. It works with anything ranging from prototype/body in white to supporting all kinds of production lines. It is versatile to any specific need. Laser Cutting 5-axis division will provide a truly world class manufacturing service. Lasersoft Changes 3D Workstation Lasersoft Changes 3D Workstation Was created for quick editing of 5 Axis Laser CNC Programs. Designed specifically for 5 Axis CNC Laser cutting machine programs. This workstation will increase the productivity of your 5-Axis Laser cutting department by freeing the machine of tasks that can be done offline in a very simple, user-friendly workstation.

LC3D you will make changes accurately, quickly and easily so you can keep your machines making parts, not making hand edits. With LC3D, your changes are exactly what you want, not a close estimate. Also, the software is user-friendly enough for your novice programmers and operators to make changes directly to the CNC program (no re-posting required). All this in a simple, visually intuitive interface; that looks and feels like a high-end CAD system, without the complexity. LC3D is designed to manipulate the geometry of non-block deleted commands. Without Lasersoft Changes 3D Workstation is a day of unrecoverable loss when compared to having this vital asset in your company’s technical and financial toolbox.

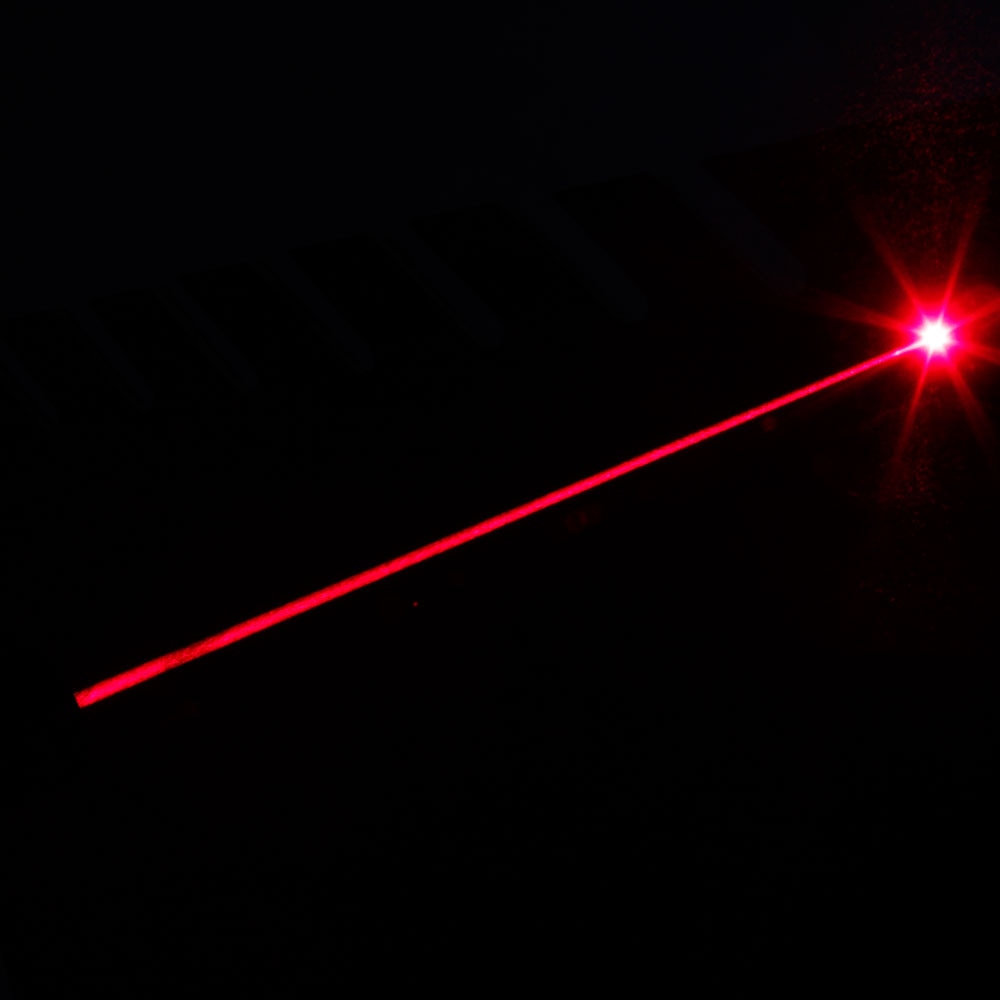

How does it work? “Laser” is an acronym for light amplification by stimulated emission of radiation. A laser is created when the electrons in atoms in special glasses, crystals, or gasses absorb energy from an electrical current or another laser and become “excited.” The excited electrons move from a lower-energy orbit to a higher-energy orbit around the atom’s nucleus. When they return to their normal or “ground” state, the electrons emit photons.

The laser beam is emitted from a laser tube when a current passed through it, this reflects off mirrors to point the beam through a focal lens in the machine head. The lens focuses the beam onto a point on the surface of a flat sheet material, melting, vaporizing or burning the material at that point and moving along the cutting line as dictated in the vector file that the machine has been provided with. This melting and vaporization of the material, especially with plastics leaves a melted, almost polished edge, requiring little to no finishing, depending on the finished purpose. Laser light is different from normal light in other ways as well. First, its light contains only one wavelength (one specific color). The particular wavelength of light is determined by the amount of energy released when the excited electron drops to a lower orbit. Second, laser light is directional. Whereas a laser generates a very tight beam, a flashlight produces light that is diffuse. Because laser light is coherent, it stays focused for vast distances, even to the moon and back. |

RSS Feed

RSS Feed